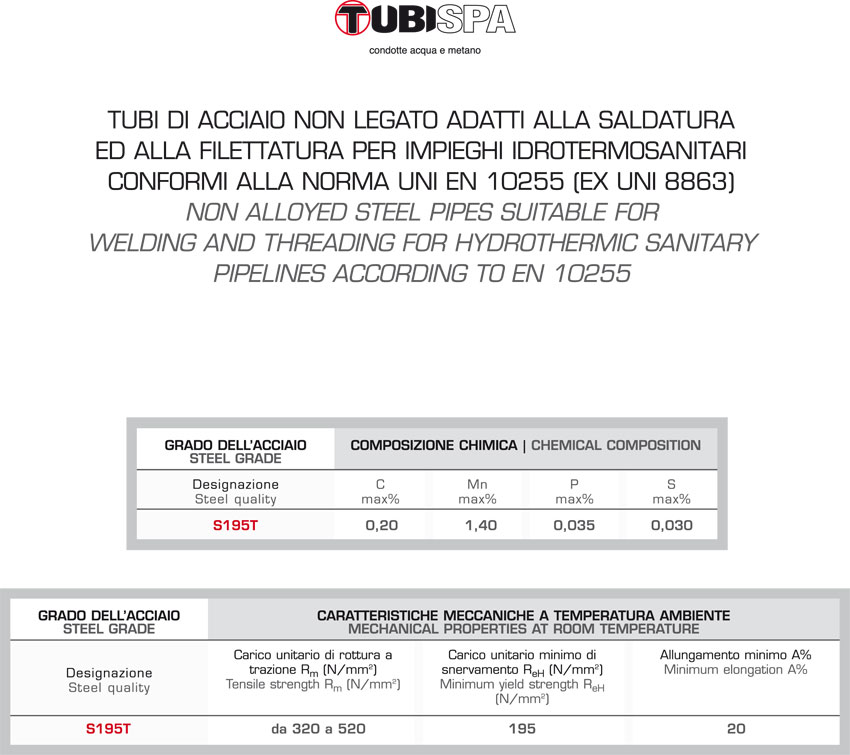

Steel pipes, welded or seamless, for water and gas pipelines, fire prevention, water and methane pipeline connections, for pressure fittings and other purposes.

Pipe Length: 5,80/6 m with -50 / +150 mm tolerance.

Pipe Ends: plain square-cut or threaded and coupled.

Surface Conditions: black (bare), galvanised according to EN 10240 A-1, prepainted (in different colours), or externally coated with bitumen or polyethylene.

Gas and water pipes

Carbon steel pipes, welded or seamless, produced according to EN 10255 standard, black or hot dip galvanized according to EN 10240 A1, with plain ends or threaded and socketed, from 1/2” to 6”.

Pipes for general purpose

Seamless steeel pipes for general use according to EN 10216-1, with plain threadable ends, from 3” to 16”.

Thermo pipes

Carbon steel pipes, welded or seamless, produced according to EN 10255 standard, externally coated with epoxy resin according to UNI 5634/97 standard, used in civil and industrial installations, which determines that the colour of the pipes identifies the fluid carried. Pipes are mainly used for fireproof installations, natural gas distribution and civil and industrial installations, from ½” to 12”.

Gas and Water distribution

Welded steel pipes, produced according to EN 10255 or EN 10208 for plumbing, are hot dip galvanized according to EN 10240 A1 suitable for drinking-water, or bare and suitable for gas; the external polyethylene coating is applied by fusion according to UNI 10191 standard or by extrusion according to UNI 9099 standard, from ½” to 4”.

Grooving

Pipe ends of welded and seamless pipes from ½” to 10” are prepared by grooving for assembling by quick couplings. These pipes are used mainly for construction of fireproof installations, production plants, industrial, mineral and naval plants and tunnels.