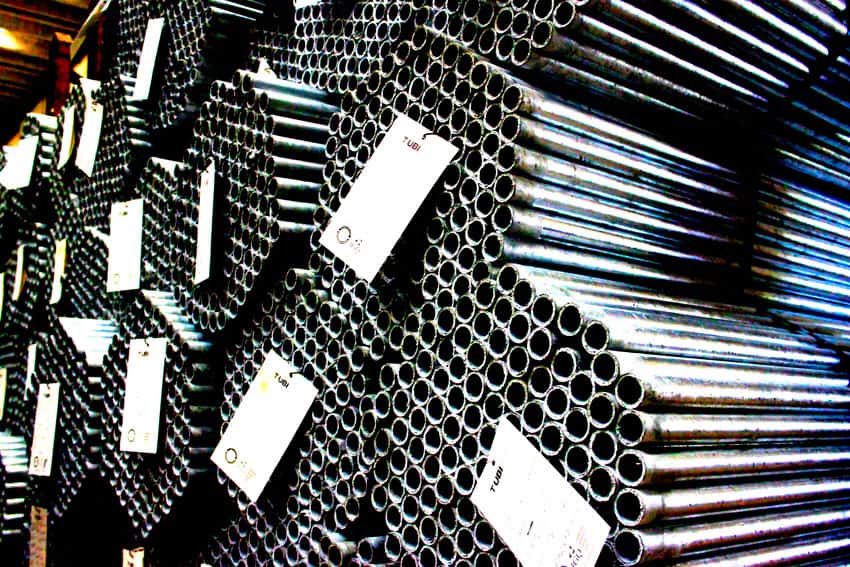

Our Rovigo factory manufactures hot dip galvanizing work according to EN 10240 A1 and B3 and thread according to ISO 7/1. In the same mill we perform external polyethylene coatings according to UNI 9099.

Galvanizing:

The steps of the pipes galvanization process are as follows:

- acid-degreasing;

- pickling;

- wash;

- flushing;

- preheating;

- tank immersion for galvanization;

- extraction;

- blow molding;

- cooling down;

- straightening;

- marking;

- packaging.

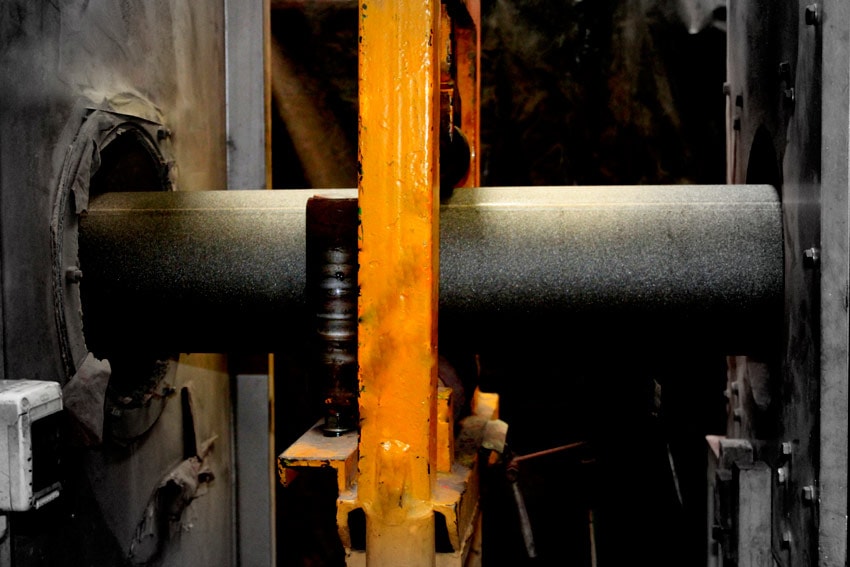

Polyethylene coating

The polyethylene coating is applied to the tubes with an extrusion system up to DN 200. This type of coating allows the following results:

- High resistance to corrosion of liquids, gases and chemicals;

- High resistance to impact and hardness test;

- High dielectric properties;

- Very high adhesion (tapping) values for a wide thermal excursion;

- Easy to repair any damage during transport or laying;

- The most commonly used material for this type of coating is Polyethylene Low Density (PEBD) and Polypropylene (PP).